Projects

Strength to Conquer the World’s High Altitudes

Tibet, known as the "roof of the world", has a harsh environment and belongs to the alpine regions of China. The local Tibetans' pursuit of home decoration and comfortable life is still at the stage of meeting basic needs. "Heating" is an important issue related to the Tibetan people's livelihood and development, especially as a school where teachers and students gather, heating work in winter cannot be ignored.The ultra-low temperature and high-power commercial inverter heat pump is BANDON’s first domestic equipment dedicated to plateau areas, creating market stories one after another. This time, with its strong product power and influence, it built a comfortable and efficient heating system for a middle school in Lhasa, Tibet, providing reliable protection for teachers and students and bringing warmth in winter.

Project Overview

A middle school in Lhasa, Tibet is located in Chengguan District, Lhasa City, Tibet Autonomous Region, in the middle reaches of the Lhasa River, a tributary of the Brahmaputra River, with an altitude of 3,650 meters and a semi-arid plateau temperate climate. The solar radiation is strong, the temperature difference between day and night is large, and the dry and wet seasons are obvious. The average temperature in winter is 4℃-7℃, with the average temperature in the coldest month of January being around -1℃ and the lowest temperature reaching -16.5℃.

The total heating area of a middle school in Lhasa, Tibet, is 42,392 square meters, which is divided into four major areas. The classroom heating demand temperature is maintained at about 18°C, the residential and dormitory temperature needs to be around 20°C, and the heating end is a radiator.

Transformation Background

This project is a newly built middle school located in Lhasa Education City, adjacent to Nagqu No. 3 High School, Lhasa Normal College, Beijing Experimental Middle School Junior High School Branch and Lhasa No. 1 Middle School Education City Branch.

After market research and on-site inspections of BANDON's project operations in southwest and other regions, the school recognized the product quality, unit stability, installation services, etc., and finally selected BANDON air source equipment to provide heating for the school and comprehensively protect the campus.

Equipment Selection

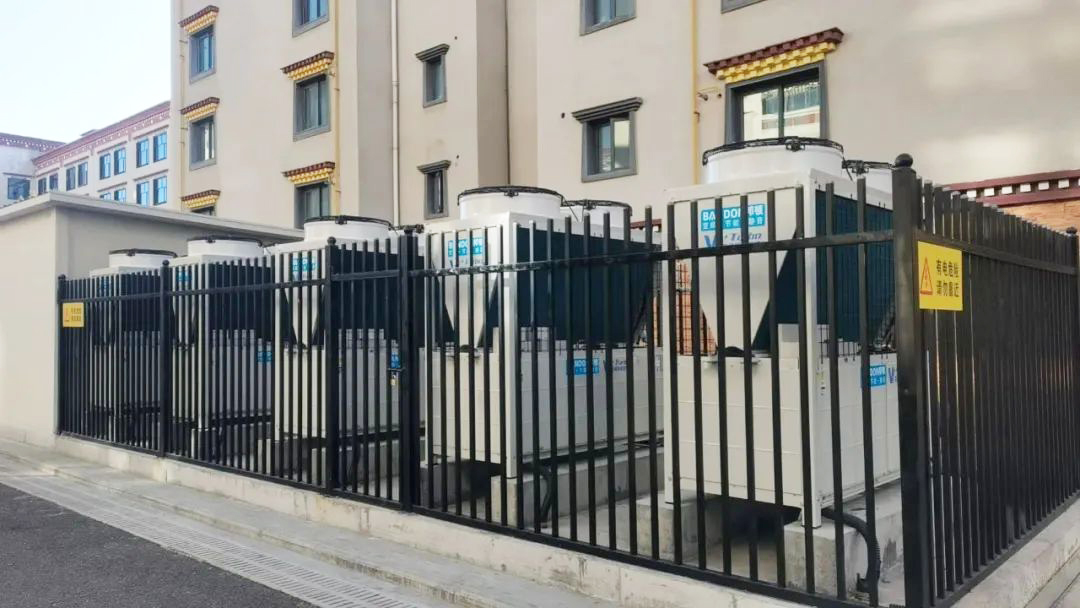

Combining local climate conditions, on-site inspection of the school building environment, and taking into account factors such as wall thickness, BANDON's technical team finally decided to equip the campus with a total 36 pcs of 40HP BANDON ultra-low-temperature high-power commercial inverter heat pumps.

As early as 2019, BANDON developed the first domestic ultra-low temperature commercial DC inverter (40 HP/80 HP) specifically for plateau areas, released and applied offline, which solved the problems of strong heat attenuation and water quality and voltage fluctuation adaptability in high-altitude and cold areas. It is stably used in high altitude areas of 5000m and cold temperature areas of -35℃, bringing clean heating to remote areas on cold plateaus. Opening up a new era of "private aircraft only" in the industry!

Device Installation

Since the heating area is relatively large and the heating needs of each area are different, point-to-point independent operation is performed. The equipment is distributed as follows:

The first area is an office building with a heating area of 3559㎡ and 3 units; the second area is 2 teaching buildings with a heating area of 8420m2 and 8 units; the third area is 6 teacher residences with a heating area of 15867㎡, equipped with 15 units; the fourth area is 2 student dormitories, with a heating area of 14546㎡, equipped with 10 units.

The BANDON installation team officially entered the site for installation and construction in March 2020. In order not to affect the winter heating of teachers and students, we accelerated the pace of installation and completed the installation and commissioning of all equipment in the shortest time. The equipment is mainly installed in the open space next to each heating area. Considering that the daily routine of teachers and students will not be affected, anti-vibration and anti-noise measures are taken during installation to create a better campus environment.

Operation Status

The project has been installed, debugged and put into use. Based on the actual usage of the school, the heating experience is continuously optimized. After BANDON air source heat pump heating, distributed and flexible heating is carried out, and intelligent control is carried out according to different time periods and different temperature requirements, which is conducive to energy saving and management, and the temperature in each area of the school meets the requirements.

Party A's Evaluation

The project is relatively complex. Heating is carried out point-to-point in different areas. The heating needs of each area are different. After the installation and debugging of the equipment was completed, the overall operation was smooth. We also conducted a follow-up visit to the school and learned that the evaluation is as follows:

①The school is very satisfied with this new heating method, which is both energy-saving and environmentally friendly;

②The equipment operates with low noise, greatly reducing the impact on the campus environment;

③The heating temperature is comfortable, reaches the required temperature, operates stably, and is intelligently controlled.