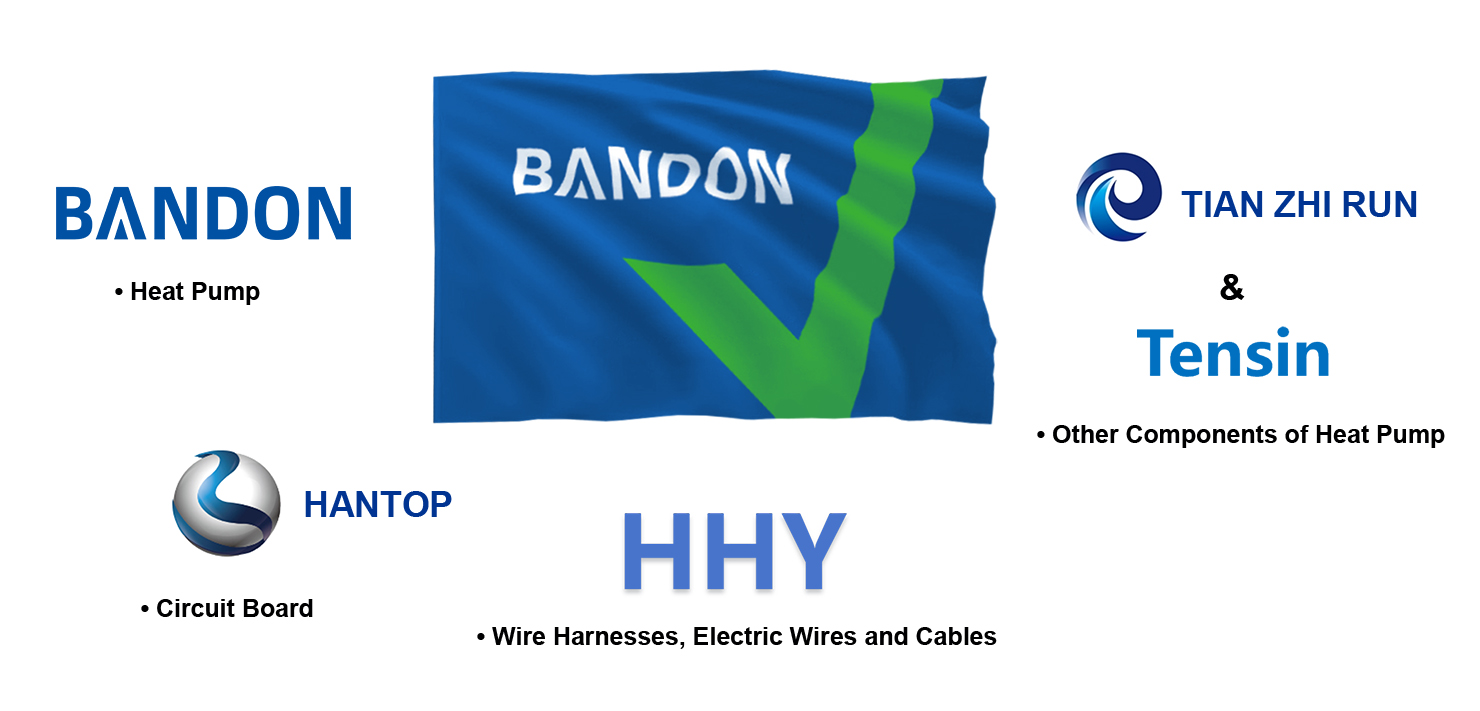

BANDON GROUP

BANDON Group is located in Foshan City, China, a well-known core area for air conditioning manufacturing. Since its establishment, BANDON has continued to grow and gradually developed into four major business segments, namely heat pumps, circuit boards, wire harnesses, electric wires and cables, as well as other heat pump components.

Heat Pump

BANDON boasts over 20 years of experience in the heat pump industry. It has integrated the research and development, design, production, sales, and service of heat pumps into one entity. Equipped with advanced technology, sophisticated equipment, superb production processes, and the strictest quality control system, BANDON provides partners with a full range of competitive products.

• Heat Pump Solutions: We offer comprehensive product solutions encompassing Swimming Pool Heating/Cooling, Space Heating/Cooling, and Domestic Hot Water (DHW). Our diverse range of products caters to various market segments, including residential, commercial, industrial, and agricultural, meeting customers' demands for a wide array of heat pump products.

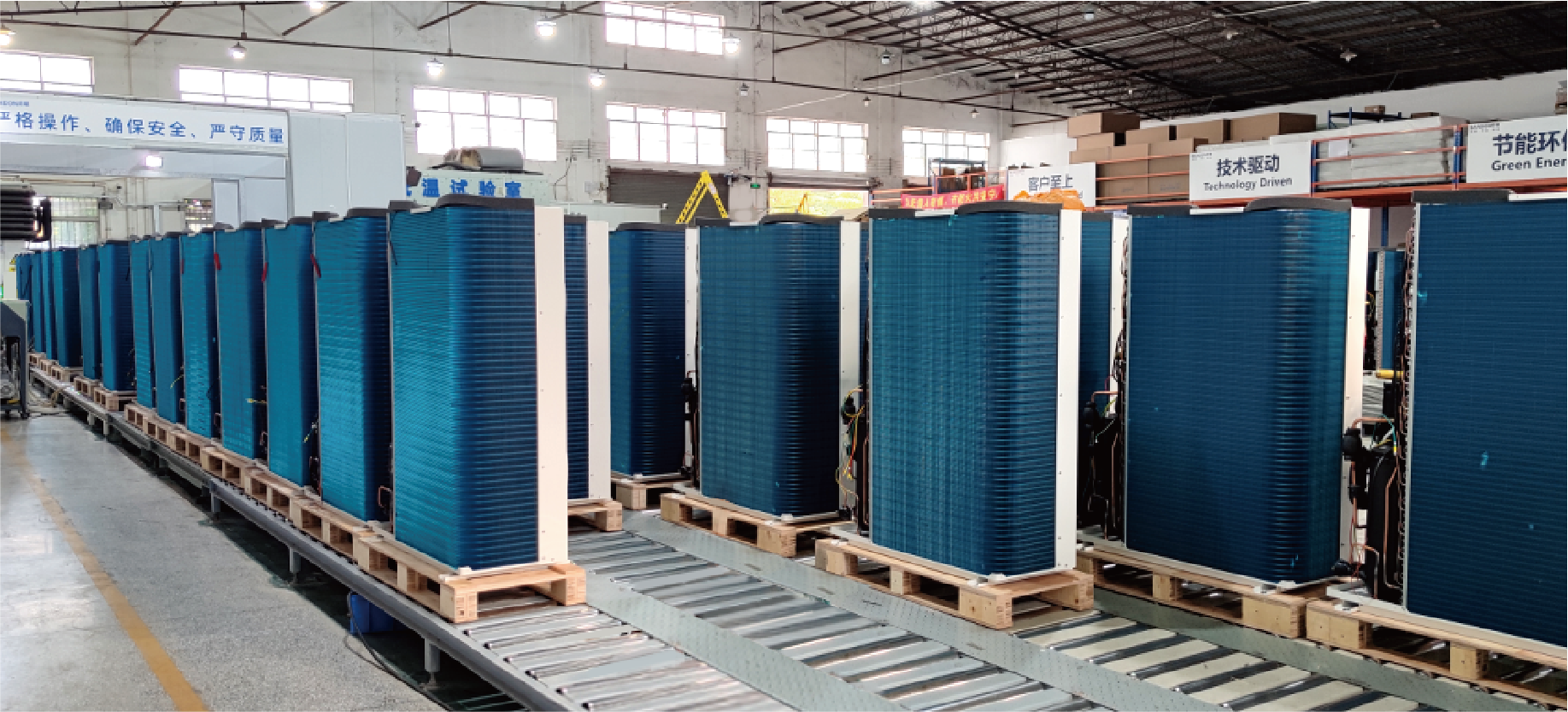

• Hardware Facilities: BANDON boasts two production bases for heat pumps, equipped with internationally-standardized heat pump finished product laboratories and noise laboratories. We possess precise equipment to test component reliability and utilize production machinery that balances both efficiency and safety, providing a robust foundation for high-quality research and development as well as production.

• R&D Strength: BANDON's research and development team is segmented into three key areas: electronic control, gas systems, and structure. With over 20 years of rich experience in the heat pump industry, these three segments collaborate seamlessly to deliver cutting-edge heat pump product solutions to customers with precision and efficiency.

• Quality Control: Our commitment to quality extends throughout the entire process of heat pump design, development, production, and application. We leave no detail unnoticed, ensuring comprehensive quality control at every stage.

• Production System: BANDON's production division boasts extensive experience in heat pump manufacturing, proficient in the production of various types of heat pump products. We adopt standardized and regulated production methods, significantly reducing production lead times and delivering efficiency in our operations.

Circuit Board

In 2018, BANDON introduced technical talents from world top 500 companies such as Hitachi and Emerson, established an electric control company, and independently developed electric control solutions, laying a solid foundation for providing customers with leading heat pump solutions.

• Software Development: BANDON’s electric control subsidiary has experienced software development engineers who can complete a full set of software development, including requirements analysis and architecture design, programming and code implementation, database design and management, software testing and quality assurance, deployment and maintenance. Combined with various practical application scenarios of heat pumps and real market demands, they provide customers with comprehensive core electric control solutions.

• Hardware Design and Manufacturing: The subsidiary also has experienced hardware engineers who can complete a series of hardware design work based on software functional requirements and structural applications, including schematic design, PCB layout design, high-speed signal integrity analysis, power integrity analysis, and manufacturing control.

• Testing and Verification: After completing software development and hardware design and production, engineers will conduct comprehensive testing and verification of the circuit board, involving functional testing, performance testing, and environmental adaptability testing, to strictly control the quality of the circuit board and ensure full compliance with customer requirements.

• Electric Control Solutions: We provide customers with a complete set of heat pump electric control solutions, including Wi-Fi and app, Modbus, IoT and OTA, etc., to help customers maintain core competitiveness in the market.

Wire Harnesses, Electric Wires and Cables

To more efficiently coordinate

with the production of heat pump units, BANDON has established a factory for

wire harnesses, electric wires and cables. The design and production of these

materials involve a complex and intricate process that spans multiple

professional fields, as outlined below:

• Material Selection: The

performance of wire harnesses, electric wires and cables is largely determined

by the materials used. Therefore, it is crucial to select suitable conductor

materials (such as copper, aluminum, etc.), insulation materials (such as PVC,

XLPE, silicone, etc.), sheathing materials, and shielding materials. These

materials must meet relevant industry specifications, including requirements

for temperature resistance, voltage resistance, flame retardancy, and

environmental friendliness.

• Design and Development: Design

is the initial step in the production of wire harnesses, electric wires and

cables. Based on customer needs and application scenarios, designers need to

determine key parameters such as conductor cross-sectional area, insulation

thickness, sheath type, and shielding structure. In addition, considerations

must be given to cable flexibility, wear resistance, corrosion resistance, as

well as the type and location of connectors. The design phase typically

requires detailed electrical and mechanical performance testing to ensure the

rationality and reliability of the design.

• Quality Control and Testing: Quality control is a crucial aspect of ensuring that wire harnesses, electric wires and cables meet quality requirements. Multiple quality tests are conducted during the production process, including conductor resistance testing, insulation resistance testing, voltage withstand testing, high-temperature aging testing, and more. These tests ensure that the electrical and mechanical performance of the products meets design requirements. In addition, routine inspections such as visual inspections and dimensional measurements are also performed to ensure that the appearance and dimensions of the products meet specifications.

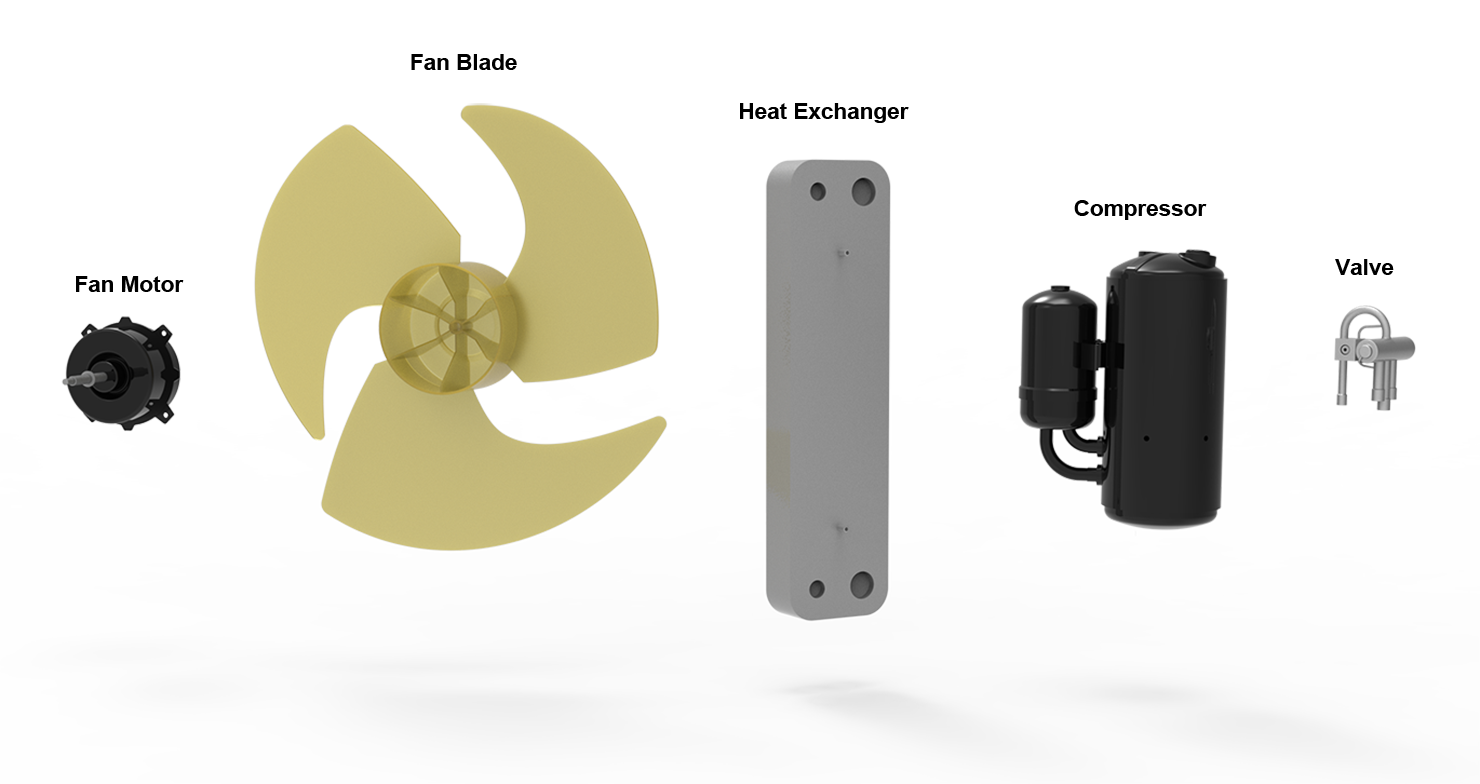

Other Components of Heat Pumps

To further ensure the production

and delivery of heat pump products within the shortest possible time, BANDON

has established a dedicated subsidiary for component procurement, which

provides a more comprehensive supply chain guarantee for heat pump production

by offering the following advantages:

• Extensive Product Range and

Inventory: Our heat pump component procurement company covers a wide range of

components required for heat pump production, including compressors, heat

exchangers, four-way valves, electronic expansion valves, motors, pressure

switches etc. We have established long-term partnerships with multiple renowned

component manufacturers, ensuring product diversity and supply stability. In

addition, we maintain adequate inventory to quickly respond to urgent customer

needs, reducing production or after-sales delays caused by waiting for

components.

• Stringent Quality Control

System: Fully aware of the importance of quality in heat pump production, we

have implemented a rigorous quality control system. From supplier selection,

raw material inspection to finished product testing, we strictly monitor every

step to ensure that the components we procure meet industry standards and

customer quality requirements.

• Professional Technical Support

and Service: Our team consists of experienced technical experts who are not

only familiar with the performance characteristics of various heat pump

components but can also provide targeted technical support and solutions to

customers. Whether it's product selection, installation guidance, or

troubleshooting, we can offer timely and professional services to help

customers improve production efficiency and product quality.

• Flexible Customization

Capabilities: To meet the diverse needs of customers, we offer flexible

customization services. Customers can customize components according to the

characteristics and requirements of their own products. Our design team works

closely with manufacturers to ensure the accuracy and applicability of

customized components.