Quality Control

BANDON owns a comprehensive and robust quality control system, regarding product quality as the lifeblood of the enterprise. From the initial design of heat pump products to research and development, and finally to mass production, we achieve all-round quality control at every stage, leaving no detail unchecked, and make every effort to provide our partners with the most reliable and trustworthy product solutions.

Design Stage

Design is the initial stage of heat pump products from scratch. In order to implement the design work, we have fully considered all aspects related to heat pumps when initiating the project, the most important of which are standards, components, and structure.

1. Standards: When designing heat pump product solutions, we have fully considered the requirements of international standards to ensure that the quality of the products we produce can meet various standards, allowing customers to sell the products without any concerns.

2. Components: The quality of components plays a crucial role in the overall product quality. To ensure the best quality level of our products, we have adopted well-known brands for all types of heat pump components and conducted rigorous selection and control from the source.

3. Structure: During the design phase, we have taken full account of important factors such as the internal layout of the heat pump, production efficiency, after-sales convenience, and operational stability. We have continuously optimized the product structure to maximize its reliability.

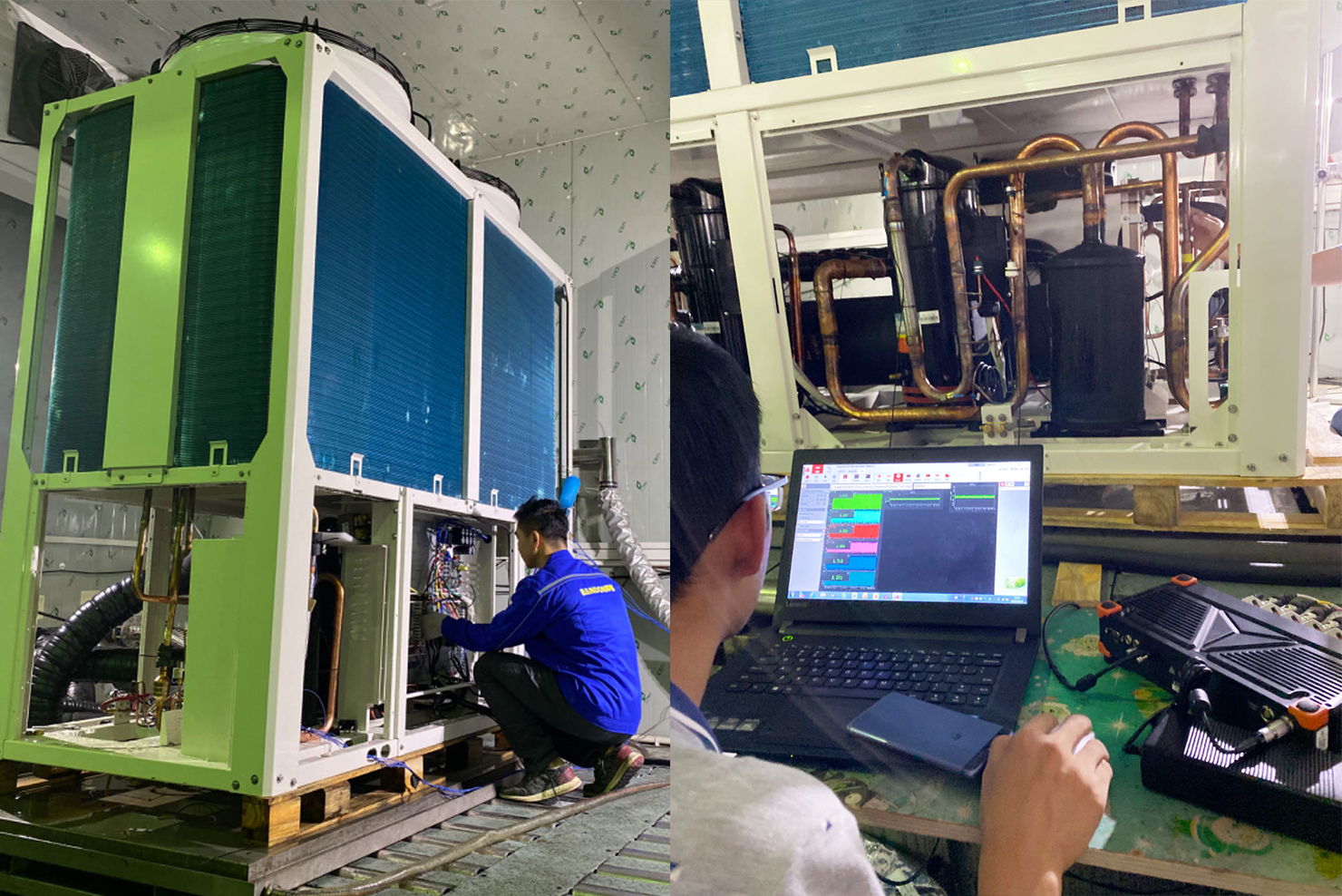

Research and Development Stage

After completing the design work, we enter the important research and development stage. From the perspective of product research and development, our quality control work focuses on unit testing, professional evaluation, and long-term operation etc, controlling every detail.

1. Unit Testing: For research and development prototypes, we conduct comprehensive testing. We have our own labs that meet international certification standards, which is used to test the performance of heat pumps (such as heating capacity, cooling capacity, COP, defrosting efficiency, etc.), as well as product functions. In addition, we have a professional noise laboratory that can accurately test the noise level of the heat pump. Furthermore, we complete vibration and stress testing within the factory to ensure that the product will not be damaged during transportation and operation.

2. Professional Evaluation: After the initial product plan is determined, we organize an internal formal evaluation where various departments provide feedback. Once the research and development prototype is assembled, we conduct another evaluation to discuss and confirm suggestions for further optimizing and improving the product plan. The quality department plays a crucial role in this process.

3. Long-term Operation: After completing the necessary improvements and creating a new research and development prototype, we install it in the laboratory for long-term operation. We simulate various operating conditions (such as ambient temperature, inlet water temperature, outlet water temperature, humidity, etc.) to test the reliability and stability of the unit under different scenarios.

Production Stage

After finishing the design as well as research and development, the product can be officially mass-produced. During the production process, the key quality control links we focus on include critical process control, patrol inspection, and spot check of finished products etc. We treat every production of the product with care, and carry out the strictest quality control for every link to ensure that we deliver the best quality products to our customers.

1. Control of Critical Processes: The critical processes in the production of heat pumps include incoming material inspection, welding, vacuum pumping, leak detection, electrical safety testing, and running test. We strictly adhere to process and quality standards for each procedure and rigorously control all details.

2. Patrol Inspection: During the production of heat pumps, quality engineers will continuously inspect the production situation on site, confirm all product and process details one by one according to quality standards and customer order requirements, and ensure that workshop workers produce completely in accordance with the requirements.

3. Finished Product Spot Checks: During the production process, we will randomly select a certain number of products, install them in the laboratory, and test and verify their performance under different operating conditions. By comparing with existing product data, we ensure the consistency of each batch of produced products.